Wuyang Textile Machinery was founded.

Increased rental of 11 workshops, moved out of the warehouse for the first time; started manufacturing warping machines and winding machines.

The company was registered, obtaining its trademark and first patent. We acquired over 8,600 square meters of land and developed the first mesh bag warp knitting machine.

Wuyang was recognized as a well-known trademark in the city. The plush warp knitting machine obtained the title of national key new product for the first time, and the plush machinery manufacturing project was added.

WUYANG was recognized as a well-known trademark in Jiangsu Province. The company purchased 15,000 square meters and 40,000 square meters of land respectively, investing in the construction of Wuyang Chengzhong Printing and Dyeing and planning the Wuyang Longyue Road Factory. We also developed and manufactured a series of warp knitting machines for producing spacer fabrics, medium-long plush fabrics, and net fabrics.

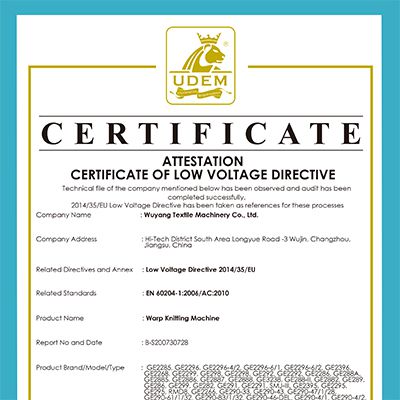

The Longyue Road factory was put into use; for the first time, we undertook national special projects and led the formulation of industry standards. Our company was also recognized as a national high-tech enterprise for the first time. A huge investment was made in the R&D of composite needle glass fiber warp knitting machine, successfully weaving semi-rigid fiberglass to provide strong power for the Tiangong-1 space station.

Wuyang trademark received key protection under national law, obtained 2 invention patents, purchased 48,000 square meters of land, and built the new Wuyang Sade factory. We once again undertook national special projects, supported the formulation of 2 industry standards, and developed computerized lace machines and seamless underwear warp knitting machine series. The company successfully held its 25th-anniversary celebration.

The brand value of "Wuyang" was evaluated at 3.8 billion yuan. Eissely was recognized as a well-known trademark in Jiangsu Province. The company was recognized as a demonstration enterprise for the integration of industrialization and informatization in Jiangsu Province and was once again recognized as a national high-tech enterprise. We supported the formulation of one national standard and undertook a successful technology transformation project in Jiangsu Province.

Co-sponsored by multiple national and industry departments, the National Knitting Industry Intelligent Manufacturing On-site Exchange Conference hosted by Wuyang and Wuyang Chengzhong Printing and Dyeing was grandly held in Changzhou, Jiangsu.

Xinhua News Agency, China News Service, China National Radio, and other media conducted concentrated interviews on the transformation and upgrading of private enterprises to our company. CCTV News broadcast a special report with the theme "Transformation of Private Enterprises in the Manufacturing Industry - Wuyang Textile Machinery: Leading the Way in Intelligent Warp Knitting for Customized Clothing".

The company was recognized by the Ministry of Industry and Information Technology as one of the first batch of manufacturing industry single-champion demonstration enterprises. Chairman Wang Minqi was selected as one of the first batch of "Grand Master of Textile Industry".

Awarded the National Intellectual Property Advantage Enterprise Award and the Second Prize for Technological Progress in Jiangsu Province.

Wuyang Group (Vietnam) factory was established in 2019 with a total investment of 16 million US dollars and covers an area of 94,035.39 square meters.

Selected as one of the top ten technological advancements in intelligent manufacturing in China.

WUYANG's "Digital Seamless Warp Knitting Equipment and Intelligent Production Management System" was selected for the 2021 "Recommended Catalogue of Advanced Technology and Equipment in the Chinese Knitting Industry". It was awarded an honorary certificate by the China Textile Industry Association, and Wuyang Textile Machinery received the "13th Five-Year Plan" Excellent Supplier Award in the Chinese Knitting Industry.

Wuyang Textile Machinery once again won the title of Single-Champion Demonstration Enterprise in the manufacturing industry.