We invite you to experience what we can do to help your business. Please give us this opportunity and you will not be disappointed.

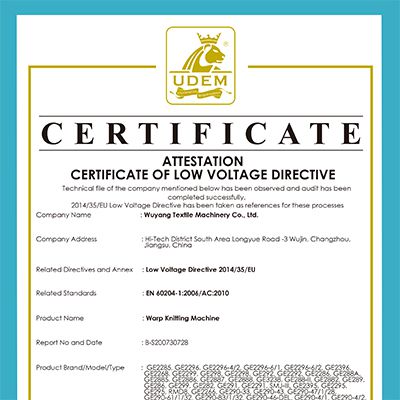

WUYANG has been focusing on warp knitting equipment for 38 years and has an advanced technical team with strong R&D capabilities. We can design and develop equipment according to customer needs. Our company has obtained 23 software copyrights, 23 national invention patents, and 3 international patents. We have completed the development tasks of 5 national standards and 5 industry standards assigned by the Ministry of Industry and Information Technology. Our company has registered 38 domestic trademarks and 48 international trademarks (including 37 Madrid trademarks).

We have a complete digital R&D system and have also established a real-time, web-based technical communication platform with our customers. Our excellent technical strength is well-known to domestic and international users. In order to further develop related equipment and technologies, we have also hired graduate students from Columbia University to plan the company's technology and overall control.

-

Environmental protection and safety Our textile machines consume only 12.5 kW per hour, with low power consumption. The machines are equipped with safety systems to prevent accidents while operators are working. Multiple emergency-stop devices are installed.

-

Cost-effectiveness WUYANG is a leading enterprise in Chinese warp knitting industry. Customers can obtain industry-leading standard machines at more favorable prices. Our machines operate stably, and after upgrading, the machine speed can reach 900-1000 rpm with significant productivity. Furthermore, our upgraded system has simplified operations. Previously, one worker could only manage one machine, but now one employee can manage 3-4 machines simultaneously, reducing labor costs and minimizing error rates.

-

Advanced intelligent system Our warp knitting machines feature a multi-dimensional embedded intelligent control system with independent intellectual property rights. The textile machine can be connected to the internet for real-time control and personalized customization is available to meet the requirements of processing diversity and flexibility. Additionally, remote technical assistance is available to solve processing issues.

- Providing complete solutions

Our warp knitting machine solutions include information collection, real-time updates on the status of each device, and a visual inspection AI system equipped with aerospace-grade cameras. The yarn breakage algorithm controls the machines to automatically stop, reducing the production of defective fabrics and creating value for customers by minimizing repetitive labor-intensive work. - Professional and personalized customization

With 38 years of custom processing experience, we have customized dozens of warp knitting equipment for global customers in various fields. Based on the requirements of your products, we can provide one-on-one customization services in terms of working width, configuration, language system, and more. If you have other customization needs, we will also provide different designs based on the situation. WUYANG aims to solve all your needs through high-quality customization. - Pre-sales, in-sales, and after-sales services

WUYANG fully considers the needs of our customers. When you see our products, we begin serving you, including pre-sales product consultation, in-sales processing and design, as well as installation, debugging, and maintenance in the later stage. We guarantee your rights throughout the entire process and address any concerns you may have, ensuring a better experience from purchase to consultation.